Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality HRC coupling.

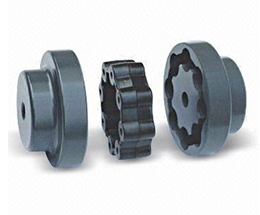

KASIN MH Shaft Couplings

1. Material:the hub of the Couplings is Cast Iron,the Elastomer is Rubbe

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

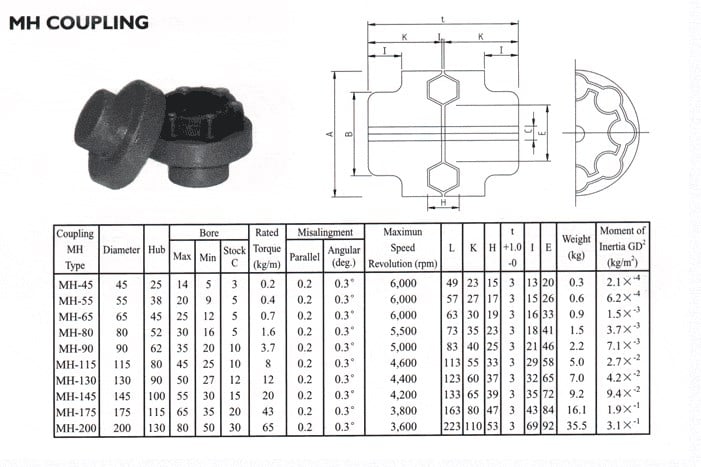

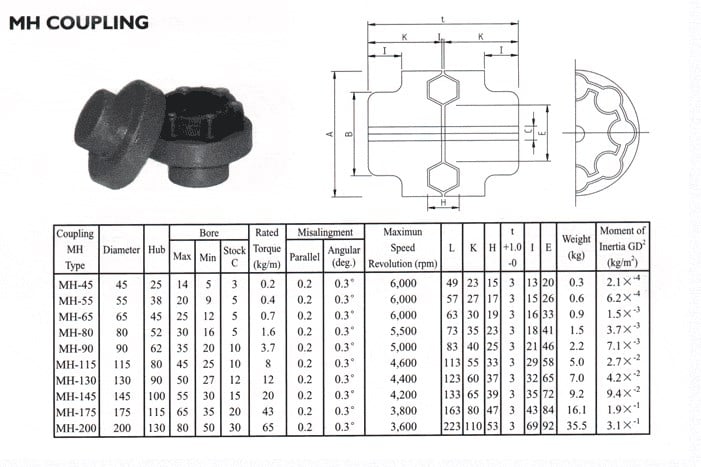

Techncial Date

Related Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Manufacturing

Applications:

NM couplings are offered in the industry’s largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 20-85 |

| Torque: | >80N.M |

| Bore Diameter: | as Your Require |

| Speed: | 3600 |

| Structure: | Flexible |

| Samples: |

US$ 100/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings accommodate high torque and high-speed applications?

Yes, flexible couplings can accommodate both high torque and high-speed applications, but the suitability depends on the specific design and material of the flexible coupling. Different types of flexible couplings have varying torque and speed capacities, and it’s crucial to select the right type of coupling based on the application requirements.

High Torque Applications:

Some flexible couplings, such as gear couplings and disc couplings, are designed to handle high torque levels. Gear couplings consist of toothed hubs that mesh with each other, providing a robust and efficient torque transmission. They are commonly used in heavy-duty industrial applications, such as steel mills, mining equipment, and power generation plants, where high torque loads are prevalent.

Disc couplings are also suitable for high torque applications. They use a series of flexible metal discs that can handle significant torque while compensating for misalignment. Disc couplings are often used in high-speed machinery and critical applications where precise torque transmission is essential.

High-Speed Applications:

Flexible couplings can also be used in high-speed applications. For instance, certain disc couplings, elastomeric couplings, and grid couplings are capable of handling high rotational speeds. These couplings have low inertia, which means they can respond quickly to changes in speed and provide efficient power transmission at high RPMs.

Elastomeric couplings, such as jaw couplings and tire couplings, are commonly used in various industrial applications, including pumps, compressors, and fans, where both torque and speed requirements are high. They offer good flexibility and damping properties, making them suitable for applications with high-speed variations and vibrations.

Considerations:

When selecting a flexible coupling for high torque and high-speed applications, several factors should be considered:

- The torque and speed ratings provided by the coupling manufacturer should be checked to ensure they meet or exceed the application’s requirements.

- The design and materials of the coupling should be suitable for the specific operating conditions, including temperature, environment, and potential exposure to corrosive substances.

- Proper alignment and installation of the coupling are critical to ensure optimal performance and prevent premature wear.

- In some cases, it may be necessary to use additional components, such as torque limiters or speed reducers, to protect the coupling and the connected equipment from excessive loads or speed fluctuations.

In conclusion, flexible couplings can indeed accommodate high torque and high-speed applications, but the appropriate coupling type and proper selection are essential to ensure reliable and efficient performance in these demanding conditions.

Can flexible couplings be used in corrosive or harsh environments?

Yes, flexible couplings can be designed and selected to be used in corrosive or harsh environments. The choice of materials and coatings plays a crucial role in ensuring the coupling’s durability and performance under challenging conditions.

Corrosion-Resistant Materials:

In corrosive environments, it is essential to use materials that can withstand chemical attacks and oxidation. Stainless steel, specifically grades like 316 or 17-4 PH, is commonly chosen for flexible couplings in such situations. Stainless steel offers excellent corrosion resistance, making it suitable for applications where the coupling may come into contact with corrosive substances or moisture.

Special Coatings:

For certain harsh environments, coupling manufacturers may apply special coatings to enhance the coupling’s corrosion resistance. Examples of coatings include zinc plating, nickel plating, or epoxy coatings. These coatings provide an additional layer of protection against corrosive agents and help extend the coupling’s lifespan.

Sealed Designs:

In environments where the coupling is exposed to contaminants like dust, dirt, or moisture, sealed designs are preferred. Sealed flexible couplings prevent these substances from entering the coupling’s internal components, thus reducing the risk of corrosion and wear. The sealed design also helps to maintain the coupling’s performance over time in challenging conditions.

High-Temperature Applications:

For harsh environments with high temperatures, flexible couplings made from high-temperature resistant materials, such as certain heat-resistant stainless steels or superalloys, can be used. These materials retain their mechanical properties and corrosion resistance even at elevated temperatures.

Chemical Resistance:

For applications where the coupling might encounter chemicals or solvents, it is essential to select a coupling material that is chemically resistant. This prevents degradation and ensures the coupling’s integrity in such environments.

Specialized Designs:

In some cases, where the environment is exceptionally harsh or unique, custom-designed flexible couplings may be necessary. Engineering a coupling to meet the specific demands of the environment ensures optimal performance and reliability.

Consultation with Manufacturers:

When considering flexible couplings for corrosive or harsh environments, it is advisable to consult with coupling manufacturers or engineering experts. They can provide valuable insights and recommend suitable materials, coatings, and designs based on the specific operating conditions.

Summary:

Flexible couplings can indeed be used in corrosive or harsh environments, provided the appropriate materials, coatings, and designs are chosen. Stainless steel, sealed designs, and special coatings are some of the solutions that enhance the coupling’s corrosion resistance and performance. It is essential to consider the specific environment and application requirements when selecting a flexible coupling to ensure optimal functionality and durability in challenging conditions.

What materials are commonly used in manufacturing flexible couplings?

Flexible couplings are manufactured using a variety of materials, each offering different properties and characteristics suited for specific applications. The choice of material depends on factors such as the application’s requirements, environmental conditions, torque capacity, and desired flexibility. Here are some of the commonly used materials in manufacturing flexible couplings:

- Steel: Steel is a widely used material in flexible couplings due to its strength, durability, and excellent torque transmission capabilities. Steel couplings are suitable for heavy-duty industrial applications with high torque requirements and harsh operating conditions.

- Stainless Steel: Stainless steel is often used to manufacture flexible couplings in environments with high corrosion potential. Stainless steel couplings offer excellent resistance to rust and other corrosive elements, making them ideal for marine, food processing, and chemical industry applications.

- Aluminum: Aluminum couplings are lightweight, have low inertia, and provide excellent balance. They are commonly used in applications where reducing weight is critical, such as aerospace and robotics.

- Brass: Brass couplings are known for their electrical conductivity and are used in applications where electrical grounding or electrical isolation is required, such as in certain industrial machinery or electronics equipment.

- Cast Iron: Cast iron couplings offer good strength and durability and are often used in industrial applications where resistance to shock loads and vibrations is necessary.

- Plastic/Polymer: Some flexible couplings use high-performance polymers or plastics, such as polyurethane or nylon. These materials provide good flexibility, low friction, and resistance to chemicals. Plastic couplings are suitable for applications where corrosion resistance and lightweight are essential.

- Elastomers: Elastomers are used as the flexible elements in many flexible couplings. Materials like natural rubber, neoprene, or urethane are commonly used as elastomer spider elements, providing flexibility and vibration damping properties.

The selection of the coupling material depends on the specific needs of the application. For instance, high-performance and heavy-duty applications may require steel or stainless steel couplings for their robustness, while applications where weight reduction is crucial may benefit from aluminum or polymer couplings. Additionally, the choice of material is influenced by factors such as temperature range, chemical exposure, and electrical requirements in the application’s operating environment.

Manufacturers typically provide material specifications for their couplings, helping users make informed decisions based on the specific demands of their applications.

editor by CX 2024-04-24

China Custom Mh Coupling with Rubber for Power Transmission Parts

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality HRC coupling.

KASIN MH Shaft Couplings

1. Material:the hub of the Couplings is Cast Iron,the Elastomer is Rubbe

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Manufacturing

Applications:

NM couplings are offered in the industry’s largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CHINAMFG purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CHINAMFG positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 20-85 |

| Torque: | >80N.M |

| Bore Diameter: | as Your Require |

| Speed: | 3600 |

| Structure: | Flexible |

| Samples: |

US$ 100/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can flexible couplings be used in both horizontal and vertical shaft arrangements?

Yes, flexible couplings can be used in both horizontal and vertical shaft arrangements. The design of flexible couplings allows them to accommodate misalignment and compensate for angular, parallel, and axial displacements between the shafts, making them suitable for various shaft orientations.

Horizontal Shaft Arrangements:

In horizontal shaft arrangements, where the shafts are parallel to the ground or horizontal plane, flexible couplings are commonly used to connect two rotating shafts. These couplings help transmit torque from one shaft to another while accommodating any misalignment that may occur during operation. Horizontal shaft arrangements are common in applications such as pumps, compressors, conveyors, and industrial machinery.

Vertical Shaft Arrangements:

In vertical shaft arrangements, where the shafts are perpendicular to the ground or vertical plane, flexible couplings are also applicable. Vertical shafts often require couplings that can handle the additional weight and forces resulting from gravity. Flexible couplings designed for vertical applications can support the weight of the rotating equipment while allowing for some axial movement to accommodate thermal expansion or other displacements. Vertical shaft arrangements are commonly found in applications such as pumps, gearboxes, turbines, and some marine propulsion systems.

Considerations for Vertical Shaft Arrangements:

When using flexible couplings in vertical shaft arrangements, there are a few additional considerations to keep in mind:

- Thrust Load: Vertical shafts can generate thrust loads, especially in upward or downward direction. The flexible coupling should be selected based on its capacity to handle both radial and axial loads to accommodate these forces.

- Lubrication: Some vertical couplings may require additional lubrication to ensure smooth operation and reduce wear, particularly if they are exposed to high axial loads or extended vertical shafts.

- Support and Bearing: Proper support and bearing arrangements for the vertical shaft are essential to prevent excessive shaft deflection and ensure the flexible coupling functions correctly.

Overall, flexible couplings are versatile and adaptable to various shaft orientations, providing efficient power transmission and misalignment compensation. Whether in horizontal or vertical arrangements, using the appropriate flexible coupling design and considering the specific application requirements will help ensure reliable and efficient operation.

How does a flexible coupling affect the noise and vibration levels in a mechanical system?

A flexible coupling plays a crucial role in controlling noise and vibration levels in a mechanical system. It can significantly impact the overall smoothness and quietness of the system’s operation, contributing to enhanced performance and reduced wear on connected components.

Noise Reduction:

Flexible couplings help reduce noise in a mechanical system through their inherent ability to dampen vibrations. When the shafts of rotating machinery are not perfectly aligned, it can lead to vibrations that are transmitted throughout the system, resulting in noise generation. The elastomeric or flexible element of the coupling acts as a vibration dampener, absorbing and dissipating these vibrations. As a result, the noise levels in the system are reduced, creating a quieter operating environment.

Vibration Damping:

Vibrations in a mechanical system can lead to increased wear and tear on critical components, such as bearings, seals, and gears. Excessive vibrations can also cause resonance and damage to the system over time. Flexible couplings can effectively dampen vibrations by acting as a buffer between the driving and driven shafts. The flexible element absorbs the shock and vibrations, preventing them from propagating to other parts of the system. This vibration damping capability not only reduces noise but also protects the system from potential mechanical failures, extending the lifespan of the equipment.

Alignment Compensation:

Misalignment between shafts is a common cause of vibration and noise in rotating machinery. Flexible couplings excel at compensating for both angular and parallel misalignment. By accommodating misalignment, the coupling reduces the forces acting on the shafts and minimizes the generation of vibrations and noise. Proper alignment through the use of a flexible coupling ensures that the system operates smoothly and quietly.

Effect on Equipment Reliability:

Reducing noise and vibration levels has a positive impact on the reliability of connected equipment. Lower vibrations mean less stress on bearings and other rotating components, leading to extended component life and reduced maintenance requirements. A quieter operating environment can also be essential for certain applications, such as in laboratories or precision manufacturing processes, where excessive noise can interfere with delicate tasks or measurements.

Applications:

Flexible couplings find application in a wide range of industries, such as manufacturing, power generation, material handling, automotive, aerospace, and robotics. They are commonly used in pumps, compressors, fans, conveyors, and other rotating machinery where noise and vibration control are critical for smooth and reliable operation.

Summary:

A flexible coupling’s ability to reduce noise and dampen vibrations makes it an essential component in mechanical systems. By compensating for misalignment and providing vibration dampening properties, the flexible coupling enhances the overall system performance, reduces noise levels, and protects connected equipment from excessive wear and mechanical failures. Choosing the right type of flexible coupling based on the specific application requirements can have a significant impact on noise reduction and vibration control in the mechanical system.

What is a flexible coupling and how does it work?

A flexible coupling is a mechanical device used to connect two shafts while allowing for relative movement between them. It is designed to transmit torque from one shaft to another while compensating for misalignment, vibration, and shock. Flexible couplings are essential components in various rotating machinery and systems, as they help protect the connected equipment and enhance overall performance.

Types of Flexible Couplings:

There are several types of flexible couplings, each with its unique design and characteristics. Some common types include:

- Jaw Couplings: Jaw couplings feature elastomer spiders that fit between two hubs. They can accommodate angular and parallel misalignment while dampening vibrations.

- Disc Couplings: Disc couplings use thin metallic discs to connect the shafts. They are highly flexible and provide excellent misalignment compensation.

- Gear Couplings: Gear couplings use gear teeth to transmit torque. They offer high torque capacity and can handle moderate misalignment.

- Beam Couplings: Beam couplings use a single piece of flexible material, such as a metal beam, to transmit torque while compensating for misalignment.

- Bellows Couplings: Bellows couplings use a bellows-like structure to allow for axial, angular, and parallel misalignment compensation.

- Oldham Couplings: Oldham couplings use three discs, with the middle one having a perpendicular slot to allow for misalignment compensation.

How a Flexible Coupling Works:

The operation of a flexible coupling depends on its specific design, but the general principles are similar. Let’s take the example of a jaw coupling to explain how a flexible coupling works:

- Two shafts are connected to the coupling hubs on either side, with an elastomer spider placed between them.

- When torque is applied to one shaft, it causes the spider to compress and deform slightly, transmitting the torque to the other shaft.

- In case of misalignment between the shafts, the elastomer spider flexes and compensates for the misalignment, ensuring smooth torque transmission without imposing excessive loads on the shafts or connected equipment.

- The elastomer spider also acts as a damping element, absorbing vibrations and shocks during operation, which reduces wear on the equipment and enhances system stability.

Overall, the flexibility and ability to compensate for misalignment are the key features that allow a flexible coupling to function effectively. The choice of a specific flexible coupling type depends on the application’s requirements, such as torque capacity, misalignment compensation, and environmental conditions.

editor by CX 2024-03-26

Industrial made in China – replacement parts – in Duisburg Germany Iron Toothed Belt Pulley for Power Transmission Parts with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 diverse branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Item specification

one.Substance:C 45# metal ,stainless steel or EPT required materials.

2.Sprockets can be manufactured in accordance the customer’s drawings

three.Warmth therapy: Hardening and Tempering, Large Frequency Quenching, Carburizing Quenching and so on according the requirements..

4. Inspection: All products are checked and analyzed completely for the duration of each and every working method and right after creation will be reinspected.

About us

HangZhou EPT Sprocket Co., Ltd. is a expert manufacturer of a variety of sprocket wheels, stainless steel sprocket wheels, non-normal sprocket wheels, large pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, equipment racks, umbrella Gear, worm gear, shaft, sleeve and EPT transmission parts makers. And according to consumer drawings, samples, size processing custom made manufacturing. The business integrates style R & D, production and revenue. In accordance with rigid generation, inspection and good quality standards, the business has set up a complete top quality method, manufacturing procedure and excellent high quality manage. The firm’s sprocket goods are of higher high quality, steadiness and longevity.

The business now has eighty sets of numerous substantial-precision CNC lathes, equipment hobbing machines, equipment shapers, tempering furnaces, quenching gear, gantry planers, common milling, sawing equipment, vertical broaching equipment, hydraulic machines and EPT processing gear, with an annual manufacturing capacity of 2 million pieces . Carburizing and quenching, nitriding, quenching and EPT warmth treatment method, area blackening, galvanizing, electrophoresis, and many others. At the exact same time, it also has higher-precision screening tools this sort of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, graphic measuring instrument, Magnetic particle flaw detectors, and so forth. The merchandise produced are broadly utilized in metallurgy, steel, chemical, textile, agricultural equipment, three-dimensional garages, packaging equipment, chemical equipment, pharmaceutical equipment, industrial and mining equipment and EPT industries. The item indicators satisfy the requirements of importing comparable products and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, The united states, the Center Ea EPT and EPT regions, and are deeply trustworthy and praised by customers.

FAQ

Q: Are you investing business or producer ?

A: We are manufacturing unit.

Q: How long is your delivery time?

A: Usually it is 5-10 days if the items are in stock. or it is 15-20 days if the items are not in inventory, it is in accordance to quantity.

Q: Do you offer samples ? is it free or further ?

A: Indeed, we could supply the sample for free of charge demand but do not shell out the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment thirty%TT in advance. 70% T/T prior to shippment.

Q:What`s the MOQ of your goods?

A:1 set,we can also deal with the sample order. and the big-quantity.

The use of first products manufacturer’s (OEM) element numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our business and the detailed alternative components contained herein are not sponsored, approved, or manufactured by the OEM.